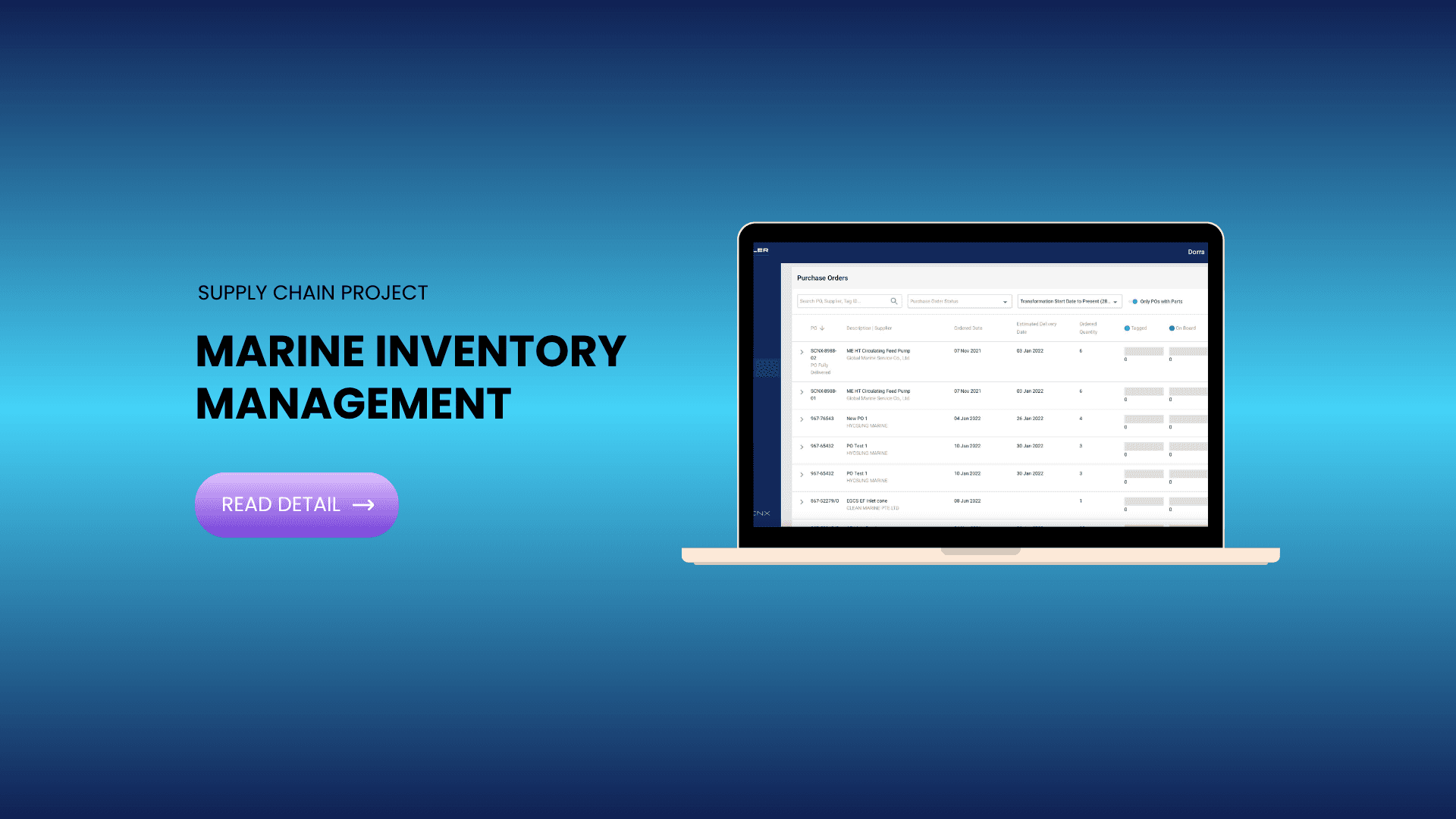

Case Study: Marine Inventory Management

A platform helps enterprises to plan sales cycles and enables them to more easily ensure they have adequate supply for their customers. Solving the challenges caused by inaccurate inventory management on board: Urgent, irregular, and late ordering makes it harder to optimize asset utilization and drives up costs; Inconsistent sales cycles; Lack of proof of delivery leading to late payments.

Key challenges

Inventory Synchronization: Accurately manage inventory across vessels, warehouses, and ports to prevent overstocking or shortages, despite ships' independent operations.

Asset & Spare Parts Tracking: Ensure timely availability of critical parts for maintenance to avoid delays and support smooth vessel operations.

Our solution

Use distributed databases to sync inventory data across vessels, ports, and warehouses. Implement offline-first mobile apps for crews to manage inventory even without connectivity.

Use digital twins to create virtual replicas of vessels for tracking spare parts usage and maintenance needs. Implement QR codes or barcodes for easy asset tracking.

Team size

10 people

2 years

Technology used

Node.js, AWS, React Native.

Book a call

More Must-Read Case Studies

Explore the innovative projects we've delivered for clients worldwide.

Our AI-powered reading technology provides an all-in-one solution for intelligent document processing. By automating text extraction and analysis, it enables fast and accurate data processing to enhance business efficiency.

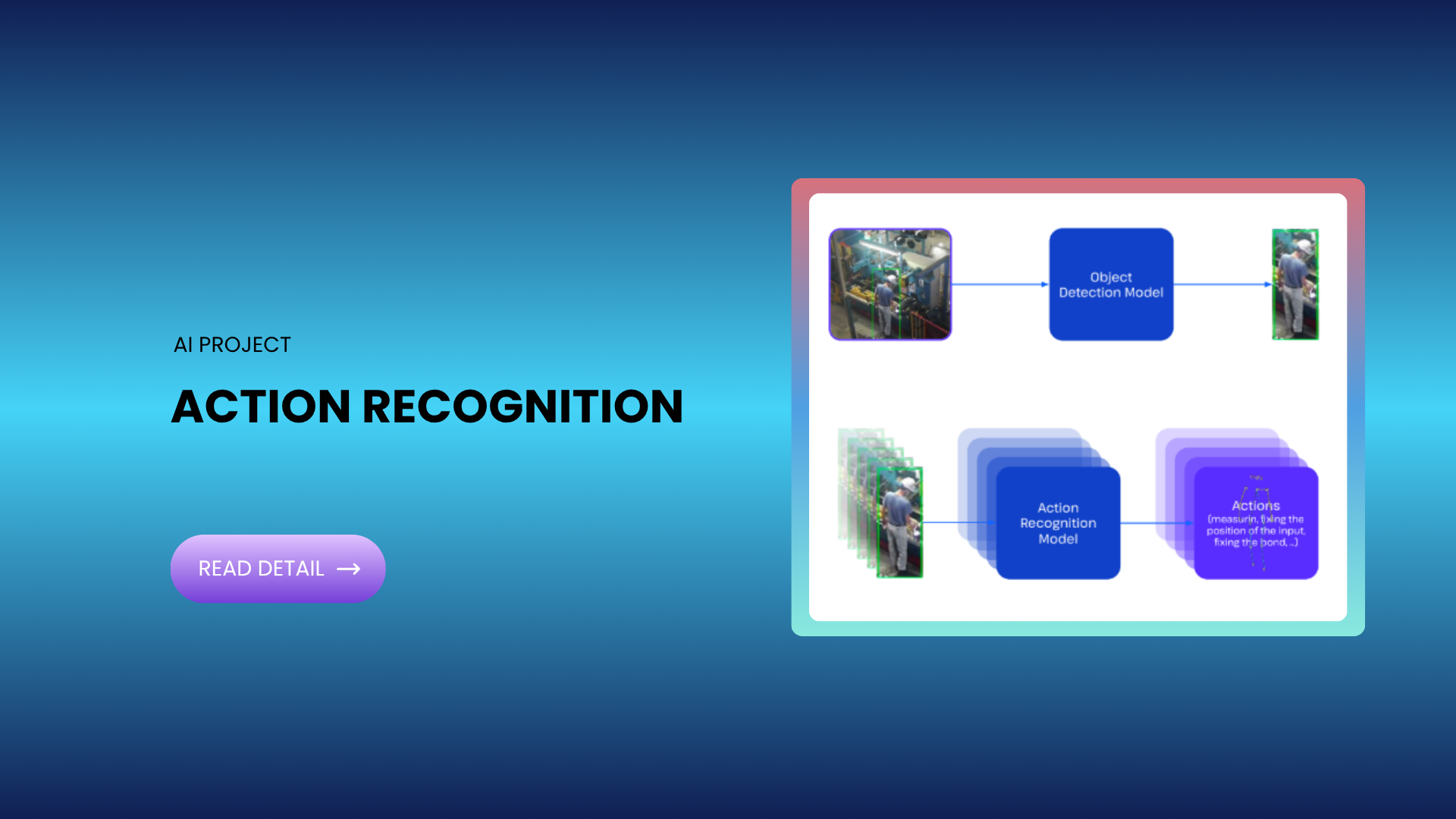

Our AI-powered CCTV solution provides an all-in-one workplace safety management and monitoring system. By enabling early detection and real-time alerts for potential hazards, it helps prevent incidents before they occur.

This project aims to enhance manufacturing process monitoring by using AI-powered action recognition to detect operator actions in response to machine errors in a factory setting.