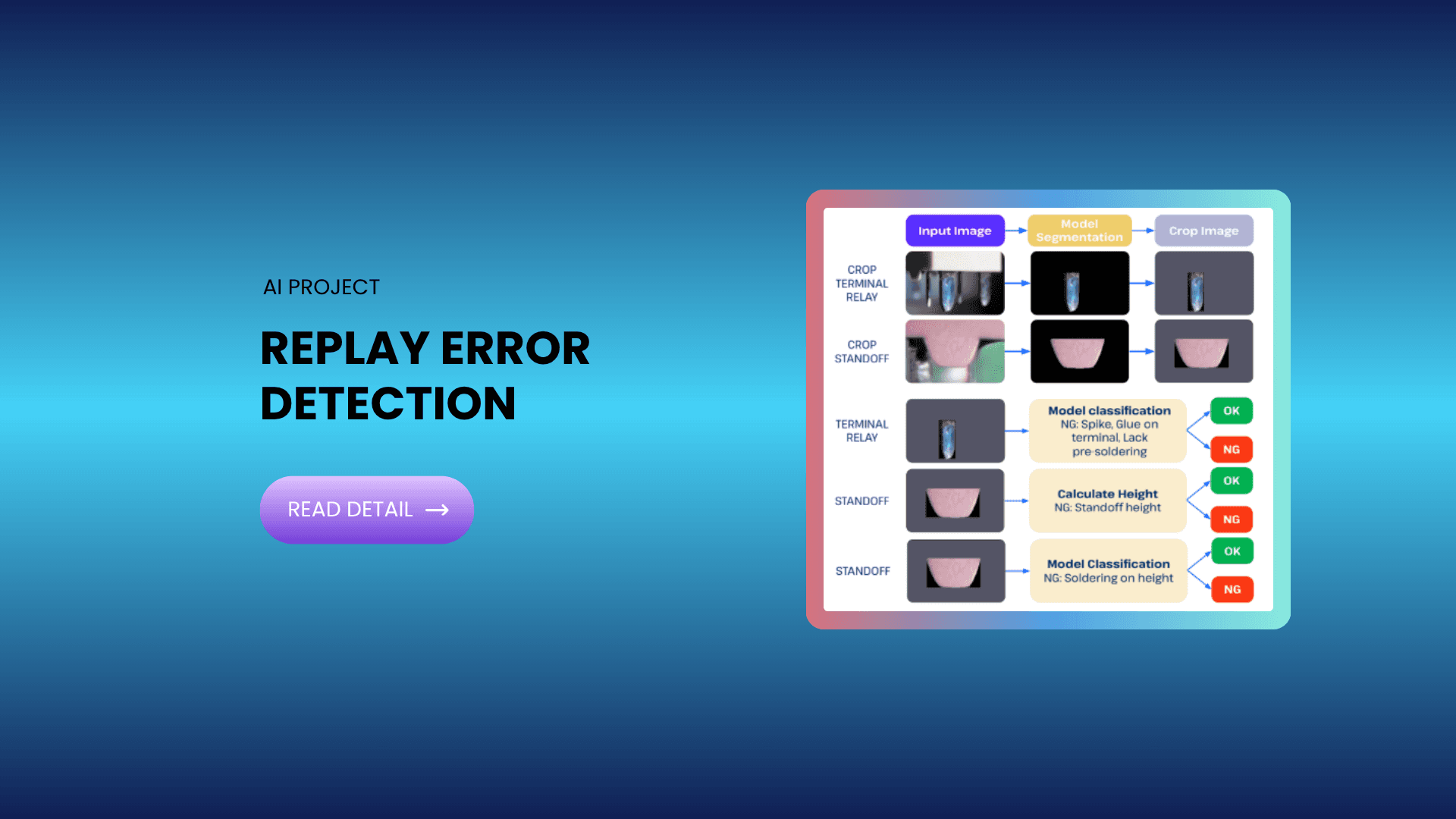

Case Study: REPLAY ERROR DETECTION

This project involves developing an AI-powered system to detect product defects on a relay production line. Previously, human visual inspection at the end of the conveyor belt resulted in low productivity and inefficient use of human resources.

Project Description

Developed an Al system to detect product defects on the relay production line.

Replaced inefficient human visual inspection to significantly improve productivity.

Business Needs

Automate defect detection to reduce manual review efforts. Identify five types of relay failures:

Spike formation

Glue on terminal

Standoff height issues

Lack of pre-soldering

Book a call

More Must-Read Case Studies

Explore the innovative projects we've delivered for clients worldwide.

Our AI-powered reading technology provides an all-in-one solution for intelligent document processing. By automating text extraction and analysis, it enables fast and accurate data processing to enhance business efficiency.

Our AI-powered CCTV solution provides an all-in-one workplace safety management and monitoring system. By enabling early detection and real-time alerts for potential hazards, it helps prevent incidents before they occur.

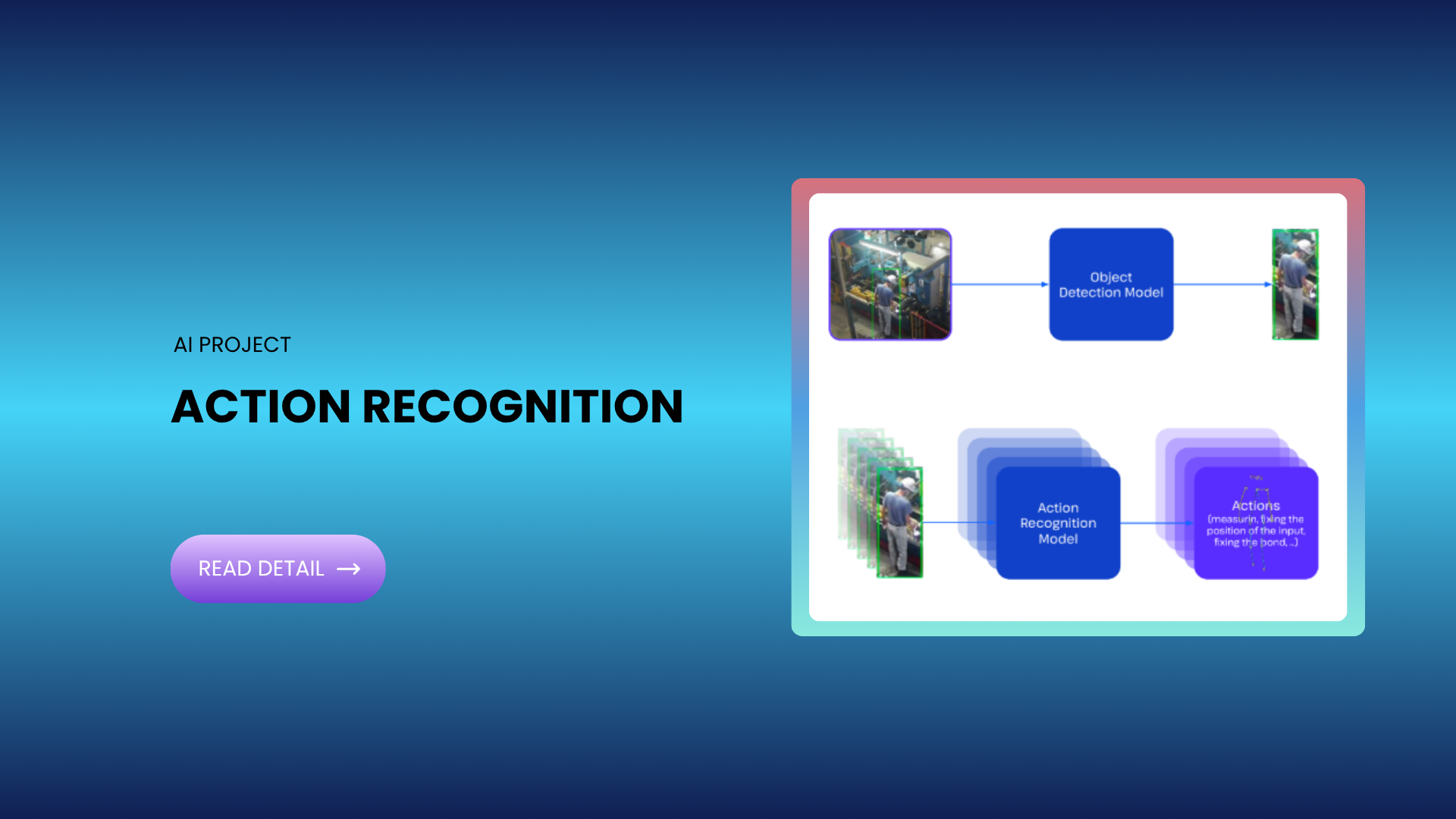

This project aims to enhance manufacturing process monitoring by using AI-powered action recognition to detect operator actions in response to machine errors in a factory setting.